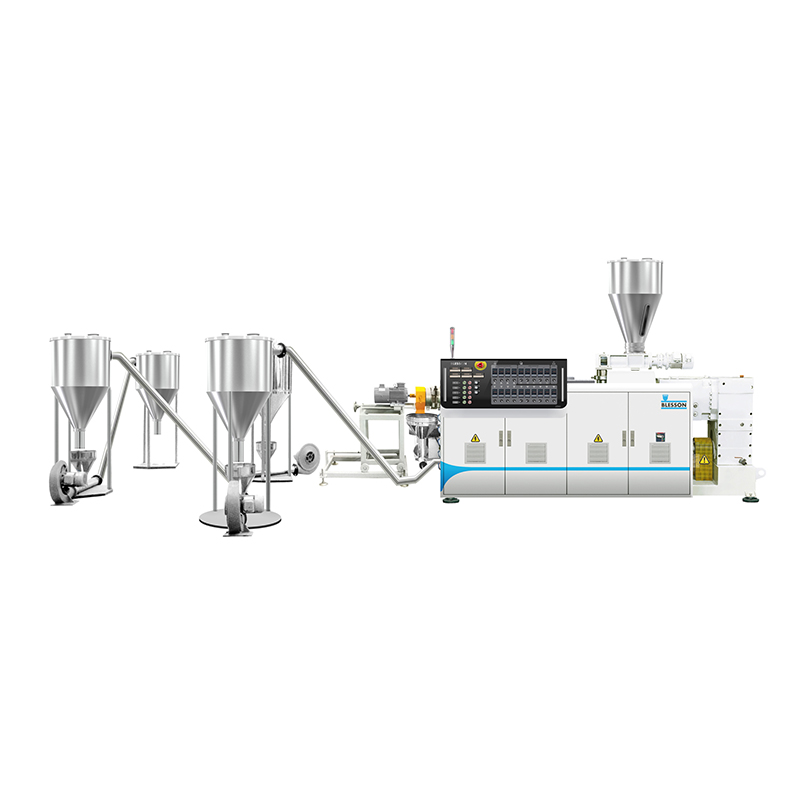

Jalur Peletisasi Plastik Kualitas Luhur

Fitur téknis utama

1. Jalur produksi diwangun ku extruder, pelletizing die, granulator, sareng alat pendingin, anu disusun sacara sederhana, sareng merenah pikeun dioperasikeun.

2. Extruder sekrup kembar kerucut kalayan desain sekrup anu unik, kaluaran anu luhur, sareng pangaruh plasticisasi anu saé.

3. Desain cetakan anu unik pikeun éfék cetakan anu langkung saé.

4. Granulator motongna rata, kalayan panutup pelindung pikeun mastikeun operasi anu aman.

5. Tangki hawa granulasi diwangun ku dua tangki pendingin sareng hiji tangki hawa panyimpenan, anu merenah sareng efisien pikeun dikumpulkeun.

Daptar Modél

| Modél Garis | Jenis motong | NgaluarkeunrModél | Maks..Kaluaran(kg/jam) | Total Daya Pamasangan(kW) |

| BLZ-65PVC(I) | potongan panas | BLE65-132G | 450 | 90 |

| BLZ-80PVC(I) | potongan panas | BLE80-156 | 450 | 120 |

| BLZ-92PVC | potongan panas | BLE92-188 | 850 | 200 |

| BLZ-95PVC | potongan panas | BLE95-191 | 1050 | 220 |

| BLZ-130PVC(I) | potongan panas | BLP130-26 | 1100 | 230 |

| BLZ-55PVC | potongan panas | BLE55-110 | 180 | 76 |

| BLZ-65PVC(II) | potongan panas | BLE65-132 | 300 | 90 |

| BLZ-65 PE/PPR | kompor tiis | BLD65-34 | 150 | 120 |

| BLZ-65 PE/PP | cincin cai potongan panas | BLE65-132 | 150 | 120 |

| BLZ-75PET | kompor tiis | BLP75-40 | 350 | 190 |

| BLZ-80PE/PPR(I) | kompor tiis | BLD80-34 | 350 | 205 |

| BLZ-80PE/PPR(II) | kompor tiis | BLD80-34 | 350 | 180 |

| BLZ-80PVC(II) | potongan panas | BLE80-156 | 450 | 170 |

| BLZ-80PVC(III) | potongan panas | BLE80-156 | 450 | 170 |

| BLZ-80PVC(III) | potongan panas | BLE80-156 | 450 | 170 |

| BLZ-92PVC(II) | potongan panas | BLE92-188 | 850 | 215 |

| BLZ-92PVC(III) | potongan panas | BLE92-188 | 850 | 205 |

| BLZ-95PET | kompor tiis | BLP95-40 | 650 | 340 |

| BLZ-130PVC(II) | potongan panas | BLP130-26 | 1100 | 240 |

| BLZ-130PVC(III) | potongan panas | BLP130-26 | 1100 | 240 |

| BLZ-150PE | kompor tiis | BLD150-24 | 280 | 340 |

Tinggalkeun Pesen Anjeun

Tulis pesen anjeun di dieu sareng kirimkeun ka kami